CNC machining is a popular choice for production used by equipment manufacturers to produce highly accurate, repeatable parts for various industries. Machines are much more efficient than other manufacturing processes and allow for less time to be used on machine setup, adjustment, and inspection of each process.

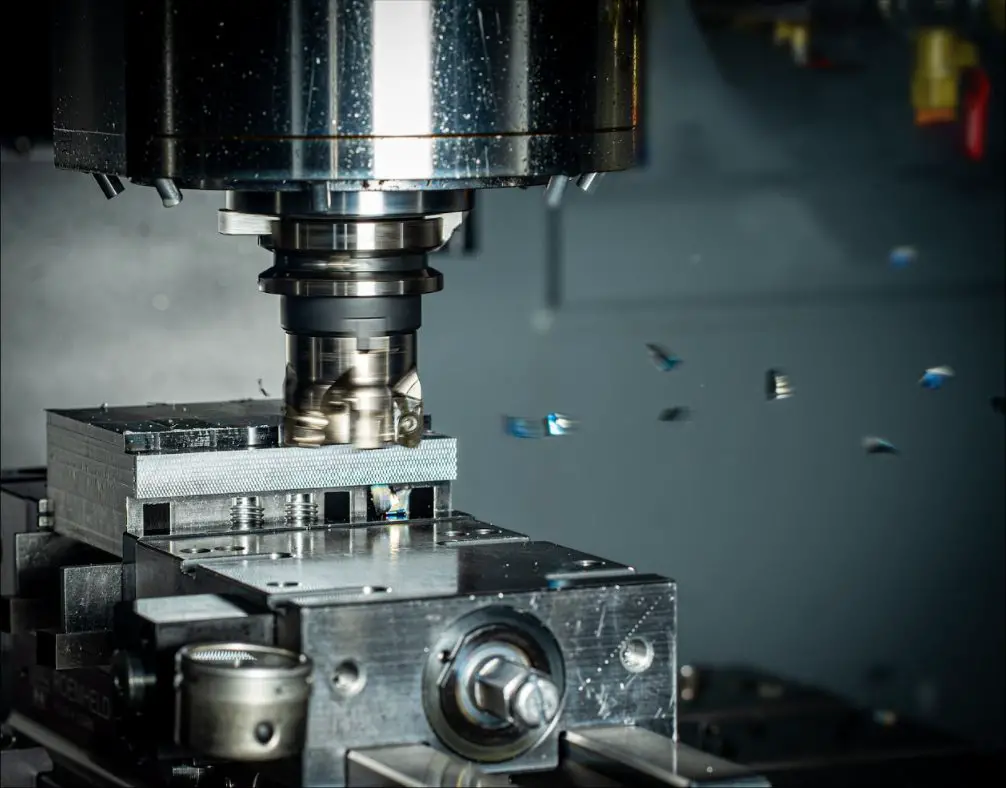

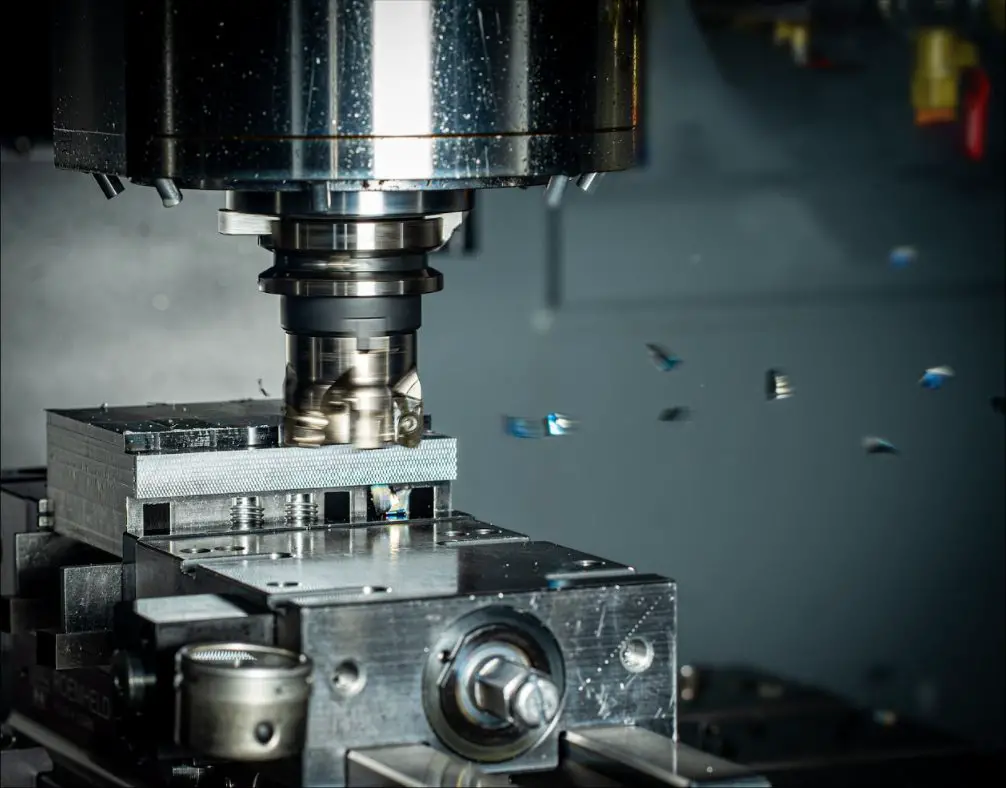

CNC milling is a cutting technique that employs rotating, multi-point cutting tools to progressively remove material from a workpiece and produce a custom-designed part or product. It is the most common type of CNC machining and can be used on a wide range of materials such as metal, plastic, glass, and wood.

The ability to customize parts is one of the key reasons CNC machining has become popular. That’s why CNC milling services are an invaluable tool for certain industries including aerospace, medical, automotive, military, and others.

What are CNC milling machines used for?

CNC milling is the process of cutting a wide variety of materials into precise structures. This method achieves efficiency, lower production times, and cost-effectiveness that is unmatched by conventional machining processes. CNC milling machines are great for profile, cavity, surface contours, and die-cutting-related machining because they offer simultaneous control of two or three feed axes.

These machines have evolved to meet the diverse needs of industries like automotive and medical, and are now becoming commonplace in small shops as well. In short, this type of machine can be used with any industry requiring precise components, including complex industries such as military and aerospace.

Application of CNC milling machines in various industries

Medical

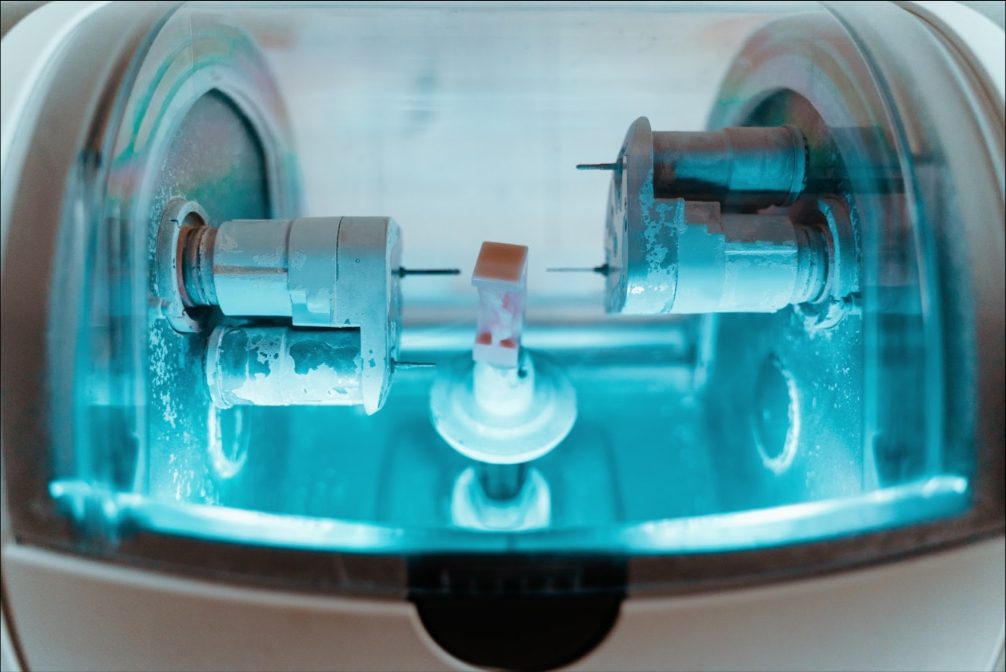

Medical equipment manufacturers use CNC milling machines and lathes to produce their products, like prosthetics that need specific designs. This technique helps with the design aspects and speed of various metal, plastic, and other substrates of medical equipment so that you can be the first to come out with innovative new products.

This process is suitable for one-off jobs, which means it has a whole range of applications in the medical industry. CNC machining can provide tight tolerances, essential for high-performing components in the medical sector.

Aerospace

CNC milling has become a prominent process for the manufacturing of many different machines and aviation parts. It standardizes the manufacturing process and ensures perfect accuracy. Aerospace machinery utilizes a variety of different materials, including special hard metals and gear, to make parts that can be used for decorative purposes or even as critical components.

A CNC mill is a great fit for materials like Inconel, a nickel-chromium alloy that turns hard at high temperatures and is used in jet engines. Milling is also an essential technique for manufacturing precise steering equipment.

Automotive

Automakers have been using new technologies to simplify production since the introduction of Henry Ford’s Model T in 1908. Automated assembly lines have been improving in efficiency, and CNC machining is one of the most valuable tools in the automotive industry. With electronic products being a major industry, this process can improve their quality. Manufacturers know that when it comes to certain parts, there’s nothing better than CNC milling machines and lathes.

These tools are especially suited for shaping plastics, as well as conductive metals and non-conductive dielectric materials. There are several configuration options for any motherboard or other components, and the difference between a good and bad component can come down to those small configurations. Milling can create tiny engraved figures, machined depressions and holes, and other complex features of precision electronic parts.

Military

Modern CNC milling machines were created based on manual machine tools 200 years ago. These were used to make uniform weapon parts for the military back then. The defense industry relies heavily on CNC milling and turning techniques. These machines are used to manufacture prototypes and mass-produced parts for planes, tanks, electronics, and more. This tradition continues as the industry is always looking for ways to improve its designs for combat readiness.

Energy

Manufacturing in the energy industry often involves the use of CNC milling to create parts for different applications. Nuclear power plants may need especially fine parts, and natural gas and oil industries also depend on this process for uninterruptible production of containers that carry fuel. Hydroelectric, solar, and wind energy suppliers also use CNC milling and turning to produce components that ensure 24-hour power generation.

Another industry where tight tolerances are necessary is the oil industry. They make use of CNC milling machines when manufacturing precise and reliable objects like pistons, cylinders, rods, pins, and more, which are usually used in oil refineries or pipelines.

Final thoughts

CNC milling is the process of using computer-controlled machine tools to create a finished product from raw materials. It has many applications in various industries. Keep in mind that no matter your industry or niche, there will be a CNC milling practice that suits you.